Steels and superalloys for energy applications

Ceit has an important activity in the optimization of manufacturing processes for improved steels and superalloys for energy applications:

-

Microstructural control for improved material performance under harsh service conditions: high temperature applications, deep/sour oil and gas wells,…

-

Microstructure / property relationships

-

Degradation and failure mechanisms: Aging, oxidation, creep, corrosion,… Cyclic conditions and overlapping of mechanisms: thermomechanical fatigue, creep-fatigue. Temperature gradients and thermal shock, wear, radiation. Mechanical properties.

-

Surface treatments (i.e. shot peening). Investigation of surface reactions and mechanisms at high temperature

-

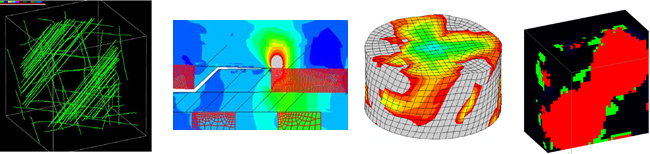

Modeling

-

Bimetallic bonding and production of components through: thermomechanical processes, hot-pressing, HIP and high vacuum furnaces.

-

Hot Isostatic Pressure (HIP) for powder consolidation: atomization, can design and manufacture, HIP, final machining. Alternative to forging plus machining.