Mechanical Design and Assessment

Our added value

A "tailored suit" made by expert researchers in mechanics, materials engineering and computing that:

-

Design, analyze and evaluate machines and components from idea (supported by solid mathematical calculations) to manufacturing through dynamic analysis, redesign or ad hoc test benches.

-

They optimize processes for forming materials both hot and cold (rolling, forging, HIP ...).

-

They offer integrity and prediction of the life of components, developing techniques that evaluate the integrity of the structure and detect eventual failures in it.

Our research lines

-

We characterize machines and processes by determining characteristic parameters from theoretical models and experimental measurements. Structural transmission of noise and vibrations.

-

Mechanical design of flexible mechanisms (Flexures) for couplings and robotic manipulators. Machine design. Thermomechanical design of refrigeration systems.

-

Material shaping modeling: hot and cold forging and shaping processes based on finite element techniques and advanced constitutive equations.

-

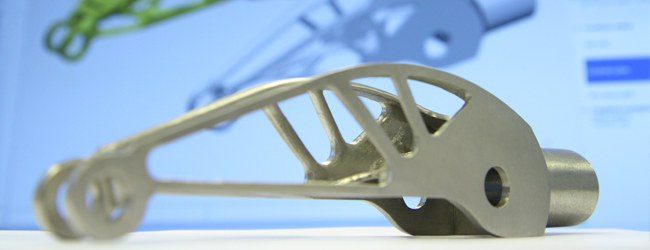

Modeling of distortions in powder metallurgy and additive manufacturing.

-

Optimization of tooling and die design in processes close to final form.

-

Study and modeling of fracture, fatigue, thermomechanical fatigue and prediction of life in complex states of load and high temperature. Development of experiments, monitoring for early detection of cracks, and component testing.

-

Micromechanical tests for the characterization of thin films and coatings, interfaces, steels, modified surfaces.