Steel forming

We have been providing technological support and solutions for over 40 years to companies involved in steel forming, with a view to boosting competitiveness. We develop industrial-oriented R&D projects that focus on improving end properties and in-service behaviour of materials, as well as optimising manufacturing processes of components with high added value.

Solutions

New ranges of sustainable steels with high added value

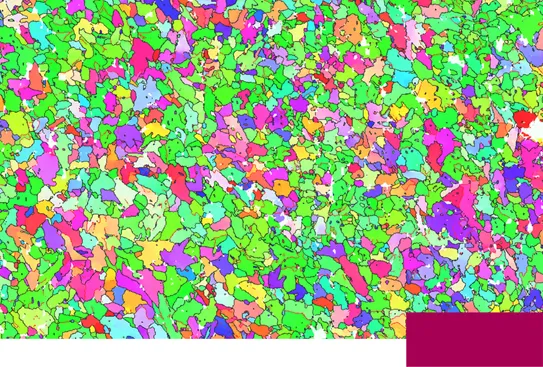

We design new compositions and grades of steel with a view to obtaining diverse properties (hot ductility, mechanics, oxidation, corrosion and thermo-influence, etc.), which are required for use in myriad applications and to reduce the product’s carbon footprint, including microalloyed steels, stainless steels and superalloys. All this is based on knowledge of correlations between evolution of the material microstructure and mechanical and structural properties of the components, created from test tubes tested on a laboratory scale.

Optimisation of processes

We develop and model thermo-mechanical and thermal treatment processing routes for long and flat products, tubes and forged components. Additionally, we analyse manufacturing process parameters with a view to improving productivity, efficiency and sustainability based on expertise in metallurgy and the physical simulation of industrial processes. All this enables us to define new processing routes.

Steels for the hydrogen economy

We analyse the quality of steels during the course of their manufacture in hydrogen combustion atmospheres and study fragilisation of the materials used to manufacture components set aside for the generation, shipment and storage of hydrogen (high pressure, cryogenics, etc.).

Zero-defect manufacturing

We analyse deviations and non-conformities that may arise in the different forming stages. As a result, we define the optimum manufacturing route to avoid any defects and minimise any loss of material. We specialise in the development of contactless parts inspection techniques via the use of electromagnetic techniques, artificial intelligence algorithms and optical image processing, with a view to detecting surface detects and ensuring dimensional control.

Process simulation software

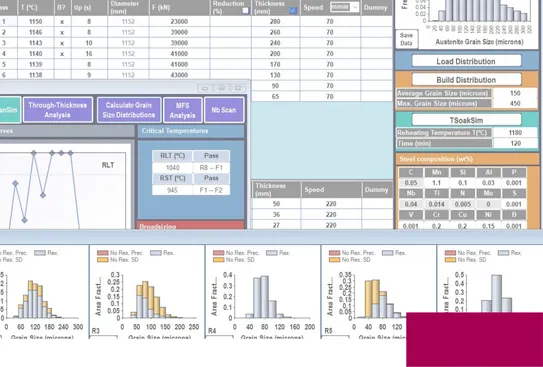

We have developed our own modelling software for manufacturing processes such as hot rolling, winding, forging, quenching and tempering, continuous annealing, and a range of conventional/induction thermal treatments, etc., with a view to ensuring greater stability and efficiency via simulation in virtual environments.

Steel-MS ®

BikiForge ®

BikiTT ®

Smart Factory

We understand smart factory to refer to a state-of-the-art production model that combines digitalisation, artificial intelligence and collaborative technologies with a view to optimising processes and guaranteeing quality. We promote efficiency via solutions such as robotics, real-time monitoring and digital twins, prioritising cybersecurity and man-machine integration. Discover how we can help you.

More Information