txt Materiales para condiciones extremas

Materials for extreme conditions

Description

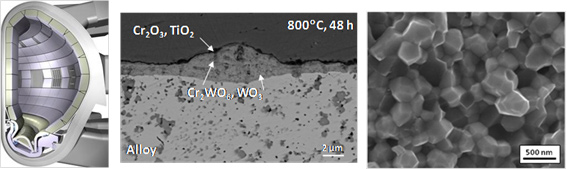

An important activity over the last decade has been the development of materials for applications in extreme conditions, among which Nuclear Fusion stands out. Ceit has been involved in different R&D projects consisting in the development of materials and components for different areas of present and future fusion devices, like ITER and DEMO: high performance graphitic materials and self-passivating, oxidation resistant tungsten-based alloys for the ivertor and the Blanket First Wall, Oxide Dispersion Strengthened Ferritic Steels (ODS FS) as structural material, as well as coated porous SiC-based materials for the Flow Channel Inserts of dual coolant blanket concepts. Finally, Ceit is also developing components by solid state diffusion bonding (HIP) to be applied at the ITER First Wall Panels.

Ceit’s capabilities and interests with regard to fusion are:

-

Development and processing metallic and ceramic powders. Equipped with atomizer to produce tailored metallic powders, and high temperature furnaces, HIP press…

-

Development of materials and components for extreme environments: graphitic materials, oxidation resistant W alloys, ODS Steels, porous SiC.

-

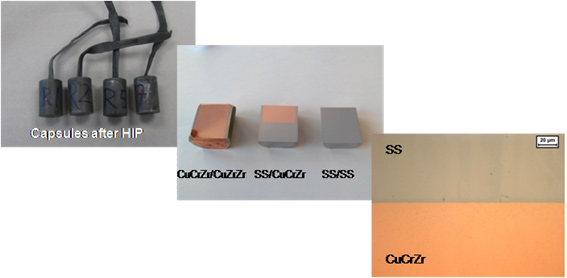

Solid state diffusion bonding. Equipped with Hot Press and HIP press. Access to industrial presses of HEDISA (only Spanish company using HIP in its manufacturing process).

-

Failure analysis: identification of failure mechanisms (fatigue, corrosion, defects, HAZ…)

-

Quality control, in-service inspection

-

Physical, Mechanical and microstructural characterization

-

Multiscale FEM of mechanical behavior (fracture, stresses…).

FUSION MAIN CONTRACTS AWARDED AND R&D PROJECTS:

-

F4E: F4E-OPE-394 (IV-PT): Fabrication of a standard semi-prototype of the ITER NHF First Wall Panels (FWP). Contribution in encapsulation before HIP.

-

F4E-OFC-167 (ES-MF) Material characterization at room at elevated temperatures. Ceit’s taks: Thermal Conductivity measurements by LFA and microstructural characterization by TEM.

-

SPAIN, MINECO “Consolider-Ingenio 2010 “TECNO_FUS”. Ceit’s task: Development of porous SiC coated with a dense SiC coating for Flow Channel Insert application.

-

SPAIN, MINECO: Development of self-passivating W-based alloys for application in fusion reactors beyond ITER

-

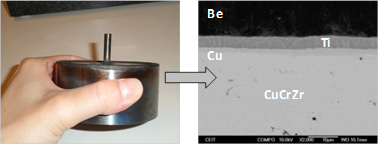

SPAIN, MINECO: ITER Blankets CDTI: Development of manufacturing technologies for ITER FWP. CEI T’s task was diffusion bonding of Be and CuCrZr by HIP.

-

EFDA: MAT-HHFM: WP 2009-2013: Manufacturing of self-passivating W based alloys for armor application (DEMO).

-

EFDA: MAT ODS FS: WP 2012-2013: Industrial production of nano-structured ODS FS following a simplified and inexpensive route (DEMO). The objective is to avoid Mechanical Alloying.

Navigation Menu

- Ceit-i buruz

- Sektore Industrialak

- Ikerketa Arloak

- Zerbitzuak eta emaitzak